Harbin University of Science and Technology Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) ( en Inventor 刘东戎 杨智鹏 杨洋 郭二军 Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Granted Application number CN201610169257.9A Other languages Chinese ( zh)

Google Patents Method for designing riser during sand casting process of thin wall casting of solid of revolution based on shrinkage defect predictionĭownload PDF Info Publication number CN105598379A CN105598379A CN201610169257.9A CN201610169257A CN105598379A CN 105598379 A CN105598379 A CN 105598379A CN 201610169257 A CN201610169257 A CN 201610169257A CN 105598379 A CN105598379 A CN 105598379A Authority CN China Prior art keywords sand casting pouring alloy foundry goods Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

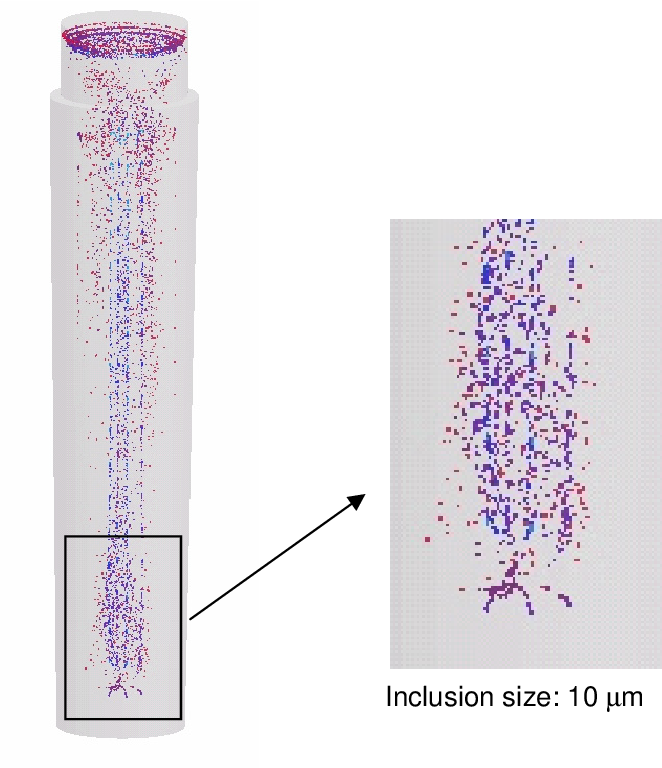

Google Patents CN105598379A - Method for designing riser during sand casting process of thin wall casting of solid of revolution based on shrinkage defect prediction Using casting process simulation, die casters gain a deeper understanding of their processes and can adjust die design, casting parameters and runner design in such ways that castings of optimal quality can be produced in economical and robust manufacturing processes.CN105598379A - Method for designing riser during sand casting process of thin wall casting of solid of revolution based on shrinkage defect prediction

Economic production aims at an optimum die temperature control, a long die life, small cycle material amounts and perfectly set machine parameters. Less scrap, reduced rework and fewer customer rejects.ĭesirable die casting processes are characterized by casting conditions that avoid gas inclusions, porosity and cold laps but at the same time provide optimal filling characteristics and short cycle times. Alucast has invested in Magmasoft casting simulation software so that we can stay at the forefront of progressive technology that can be used to realize quality castings at competitive prices thus further gaining additional customer confidence by the systematic reduction and elimination of costly casting trials and tooling modifications prior to production.

0 kommentar(er)

0 kommentar(er)